Effective supply chain management is more than just an organizational necessity – it’s a strategic advantage. Companies today face the challenge of designing their supply chains not only to be efficient but also to meet growing sustainability expectations. The pressure to reduce costs while complying with environmental standards is higher than ever.

In this blog article, you’ll learn how to improve your supply chain through various targeted measures. We explore how supply chain optimization and increased transparency can help you boost efficiency while integrating sustainable practices. From choosing the right partners to implementing processes that reduce your environmental footprint – we’ll show you how to strike the right balance between profitability and environmental responsibility.

Supply Chain Optimization: How to Make Your Processes More Efficient

Efficiency in the supply chain doesn’t just mean smooth processes—it also means using resources optimally and minimizing costs. Supply chain optimization is therefore a key component of successful supply chain management.

Process Analysis and Bottleneck Identification:

The first step in optimizing your supply chain is a thorough analysis of all relevant processes. This includes identifying bottlenecks that may cause delays or generate unnecessary costs. A detailed process analysis allows you to uncover weak points and implement targeted improvements. Tools such as process mapping and data analytics are particularly useful for quickly locating issues and developing effective solutions.

Supplier Selection and Management:

Selecting and managing suppliers is a critical element in optimizing your supply chain. Effective supplier management ensures you receive high-quality raw materials at competitive prices and that your suppliers are reliable. Regular evaluations and audits help you monitor supplier performance and identify areas for improvement.

Inventory Management and Demand Forecasting:

Strong inventory management is essential to avoid both shortages and overstocking. With accurate demand forecasting, you can better plan and adjust your inventory levels. Technologies such as Just-in-Time (JIT) and Kanban systems support efficient inventory control while reducing production costs.

Continuous Improvement:

Supply chain optimization is an ongoing process. Implementing a continuous improvement program (CIP) ensures that your supply chain adapts to new challenges and market conditions. Regular reviews and adjustments are necessary to maintain long-term efficiency and competitiveness.

Training and Employee Development:

Well-trained employees are the backbone of an efficient supply chain. Through regular training and professional development, you can ensure your team has the knowledge and skills to utilize modern technologies and manage processes effectively. Ongoing employee development helps integrate innovations faster and identify bottlenecks early.

Supply Chain Transparency: The Foundation for Trust and Efficiency

Supply chain transparency is more than just a buzzword—it’s a vital component of successful supply chain management. Transparency across the supply chain enables companies to make informed decisions, manage risks more effectively, and build trust with customers and partners. After focusing on optimizing your supply chain, the next step is to improve transparency within those processes.

Why Transparency Matters:

Transparency in the supply chain means that all stakeholders—from suppliers and manufacturers to end customers—have visibility into the various stages of the supply chain. This improves traceability of products and processes, reduces risks, and increases reliability. In a time when consumers and businesses alike are placing greater value on ethical and sustainable practices, transparency is also key to maintaining brand reputation and customer trust.

Methods to Increase Transparency:

Real-Time Data and Tracking Systems: Technologies such as blockchain and IoT enable real-time data collection and verification. These tools enhance traceability and reduce the risk of errors and fraud.

Open Communication and Reporting: Regular reporting and open communication with suppliers and customers foster better understanding and trust. Publishing sustainability reports and certifications can also contribute to greater transparency.

Collaboration with Suppliers: Engaged partnerships and involving suppliers in decision-making processes promote open and transparent communication. A supplier management program can further strengthen collaboration and improve transparency.

Challenges and Solutions:

While the benefits of transparency are clear, there are also some challenges:

Data Integration: Collecting and consolidating data from multiple sources can be complex. Implementing a centralized management system can help address this challenge.

Cost and Resources: Transparency initiatives may require significant initial investment. However, in the long term, these costs are often offset by improved processes and reduced risks.

Data Privacy and Security: Protecting sensitive information is crucial. Implementing strong security measures and complying with data protection regulations are essential to minimize risks.

The Role of Technology:

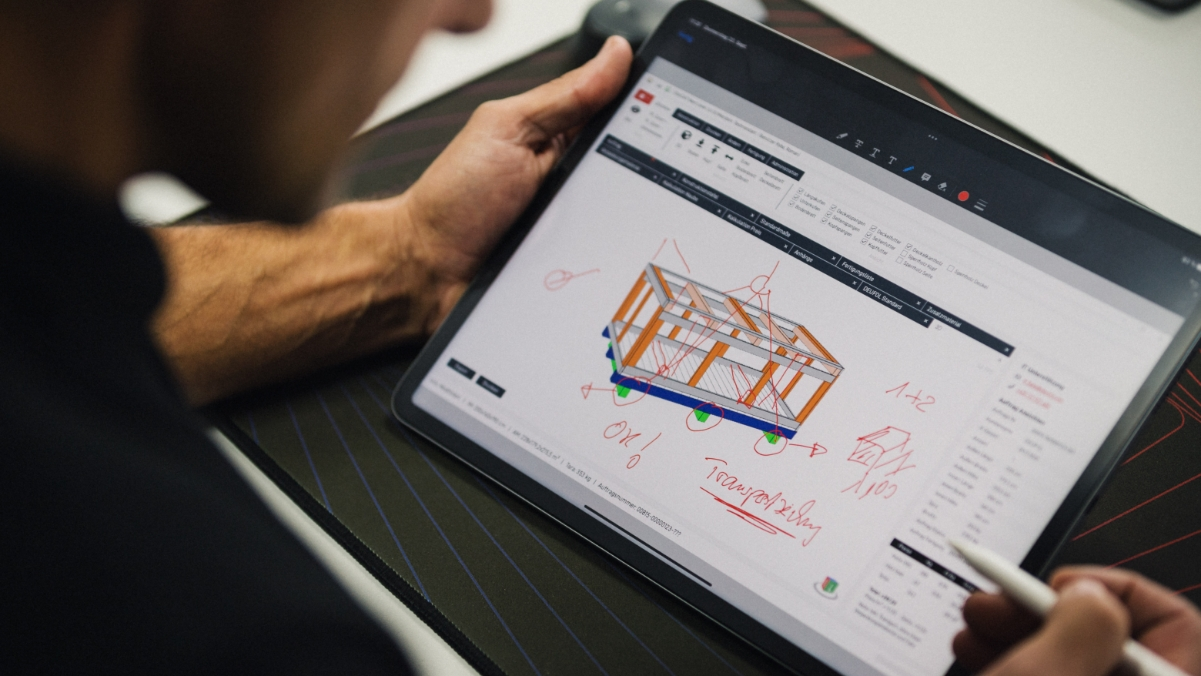

Technology also plays a key role in improving supply chain transparency. Cloud-based platforms and ERP systems allow for seamless integration and information sharing among all supply chain participants. The use of analytics and business intelligence helps identify patterns and trends that can support optimization and improved transparency.

DEUFOL, for instance, offers comprehensive end-2-end solutions that help increase transparency across your entire supply chain—enhancing both your efficiency and effectiveness.

Sustainable Supply Chain: Acting Responsibly and Environmentally Friendly

Sustainability is becoming an increasingly critical factor in today’s business world. Companies are under pressure not only to operate profitably, but also to take on ecological and social responsibility. A sustainable supply chain means designing all supply chain aspects to be environmentally friendly and aligned with ethical standards.

Why Sustainability Matters in the Supply Chain:

A sustainable supply chain considers not only the environmental impacts associated with the production and transportation of goods but also the social implications. Businesses that integrate sustainability into their supply chains can improve their environmental footprint, enhance their brand image, and meet the growing expectations of customers and investors.

Strategies to promote a Sustainable Supply Chain:

Raw Material Sourcing: Use eco-friendly materials and choose suppliers who apply sustainable practices. Review the origin of your raw materials and prioritize vendors that offer certified, sustainable products.

Energy and Resource Efficiency: Reduce energy consumption and resource usage in production and logistics processes. Technologies such as energy efficiency systems and zero-waste production approaches contribute to environmental conservation.

Transport and Logistics: Optimize transportation routes and methods to minimize CO₂ emissions. The use of electric vehicles and route planning to avoid empty runs are key measures.

Partnerships and Collaboration: Work closely with partners and suppliers who share your sustainability goals. Joint initiatives and shared goals can significantly reduce the ecological footprint of your supply chain.

Successfully Implementing Sustainable Supply Chain Management:

Implementing sustainable supply chain management requires a systematic approach, including:

Goals and Policies: Set clear sustainability goals and develop policies to support them. Integrate sustainability criteria into supplier contracts and procurement processes.

Monitoring and Reporting: Implement systems to monitor and report on sustainability performance throughout your supply chain. Regular audits and reports help track progress and identify areas for improvement.

Training and Awareness: Educate your employees and suppliers on sustainable practices and the importance of environmental awareness. This commitment at all levels is essential for the success of your sustainability initiatives.

Frequently Asked Questions about Supply Chain Management

Supply chain management includes many complex aspects and challenges. Below are some frequently asked questions that offer deeper insights and address important additional points.

How does supply chain management influence corporate strategy?

Efficient supply chain management is essential for business strategy, as it directly impacts a company’s ability to control costs, use resources effectively, and respond quickly to market demands. An integrated approach to planning and coordination helps avoid bottlenecks, improves flexibility, and ensures reliable delivery performance. Strategically aligned supply chains are also better positioned to manage risks, protect profit margins, and support sustainable growth goals.

What role does data analytics play in modern supply chains?

Data analytics is a key enabler of efficiency in today’s supply chains. With the help of big data and predictive analytics, companies can create accurate forecasts that improve demand planning, inventory control, and delivery reliability. Real-time data enables proactive decision-making, early identification of disruptions, and dynamic adaptation to changing market conditions.

What are best practices for implementing sustainable supply chain management?

Sustainable supply chain management involves selecting environmentally conscious suppliers, applying energy-efficient technologies, and continuously monitoring performance. Sustainability criteria should be embedded in procurement processes, and production and logistics should be optimized to reduce emissions. Close collaboration with partners who follow the same sustainability values is equally important for long-term success.

How can companies comply with legal requirements such as the CSDDD?

The EU’s Corporate Sustainability Due Diligence Directive (CSDDD) requires companies to systematically assess risks across their entire supply chain and take action to ensure respect for human rights and environmental standards. This involves building a risk management system, conducting supplier audits, establishing codes of conduct, and setting up monitoring and reporting processes. Complying with CSDDD strengthens transparency, ensures accountability, and helps earn long-term trust from stakeholders.

How can supply chain optimization be improved?

Supply chain optimization begins with a thorough analysis of processes to identify inefficiencies and eliminate bottlenecks. Using supply chain management software helps streamline inventory and reduce costs, while technologies such as automation and data-driven forecasting enhance visibility and decision-making. A strong focus on supplier collaboration and the integration of sustainability measures are also critical. At DEUFOL, we support companies with tailored end-2-end solutions designed to make their supply chains more efficient, resilient, and sustainable.

Our DEUFOL Conclusion

A well-designed supply chain management strategy is essential today to ensure both efficiency and sustainability. Optimizing your supply chain allows you to streamline processes, reduce bottlenecks, and cut costs. By leveraging modern technologies and fostering close collaboration with suppliers, you can implement improvements that support the long-term success of your business.

Transparency plays an equally central role in supply chain management. It enables you to better manage risks and build trust with customers and business partners. Real-time data, tracking systems, and open communication help create visibility and make your processes even more effective. At the same time, the focus on sustainable supply chains is becoming increasingly important. Sustainability means not only complying with legal requirements such as the Corporate Sustainability Due Diligence Directive (CSDDD), but also actively taking responsibility for environmental and social factors.

With DEUFOL, you have a strong partner at your side to support you in optimizing and digitalizing your supply chain management. Whether you’re aiming to improve efficiency, enhance transparency, or implement a sustainable strategy — we provide tailored solutions that meet your specific needs. Let’s explore how we can elevate your supply chain to the next level, End-to-End. Contact one of our experts today to schedule a free consultation.